Magnetic Sensors

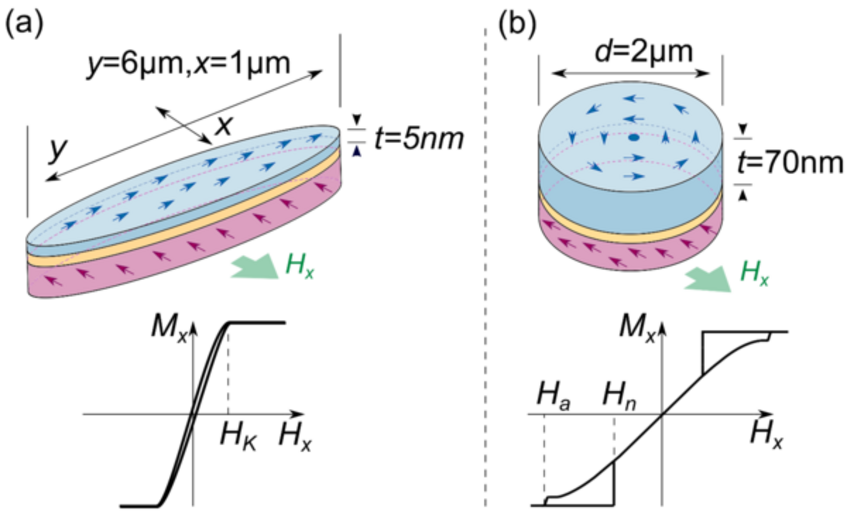

Magnetic hysteresis of (a) elliptical sensor element subject to shape anisotropy compared to (b) vortex sensor.

Magnetic sensors are used in a wide range of applications, where robust, contactless sensing is required. For example modern cars contain several magnetic sensors to measure wheel speed, transmission gear speed and position, crankshaft position, engine speed, and much more. Currently a transition from the classical Hall effect sensors to GMR (Giant MagnetoResistance) and TMR (Tunnel MagnetoResistance) sensors takes place. Compared with classical sensors, magnetoresistive sensors offer enhanced sensitivity and thus extended range and applicability.

Due to non-linear and hysteretic effects like domain wall motion or switching events, the device modeling gets challenging.

Furtunately the underlying physical processes can be well described by micromagnetic simulations. Sensor dimention in the micrometer regime require very efficient numerical methods.

Typical questions which are studied include the effects of bias fields, surface roughness, sensor layout on the overall performance of the sensor. The final goal in sensor design is to reduce non-linearity, hysteresis as well as the magnetic noise of the sensor. One very recent example for an improved sensor design is a low-noise sensor based on topologically protected vortex structures. Utilizing the stable vortex groundstate allows to significantly reduce hysteresis, while providing an extended linear range.

Selected Publications

- Suess, Dieter, et al. "Topologically protected vortex structures for low-noise magnetic sensors with high linear range." Nature Electronics 1.6 (2018): 362-370.

- Bachleitner-Hofmann, Anton, et al. "Magnetic sensor device and method for a magnetic sensor device having a magneto-resistive structure." U.S. Patent Application No. 15/375,995.

- Brueckl, H., et al. "Vortex magnetization state in a GMR spin-valve type field sensor." Magnetics Conference (INTERMAG), 2017 IEEE International. IEEE, 2017.

- Bachleitner-Hofmann, Anton, et al. "Unexpected width of minor magnetic hysteresis loops in nanostructures." IEEE Transactions on Magnetics 52.7 (2016): 1-4.

- Bruckner, Florian, et al. "A device model framework for magnetoresistive sensors based on the Stoner–Wohlfarth model." Journal of Magnetism and Magnetic Materials 381 (2015): 344-349.